exocad’s constantly expanding verified component library databases contain a leading number of supported dental components. It is important to support the newest dental innovations right from the start. That’s why we support our partners, official resellers and dental component manufacturers to make the integration process of new and updated component systems as easy and efficient as possible.

To enable us to use your data within our software systems, it’s required to form a License Agreement. This License Agreement also allows us to use your company name, trademarks and related imagery/parameters within our software systems for displaying and advertising.

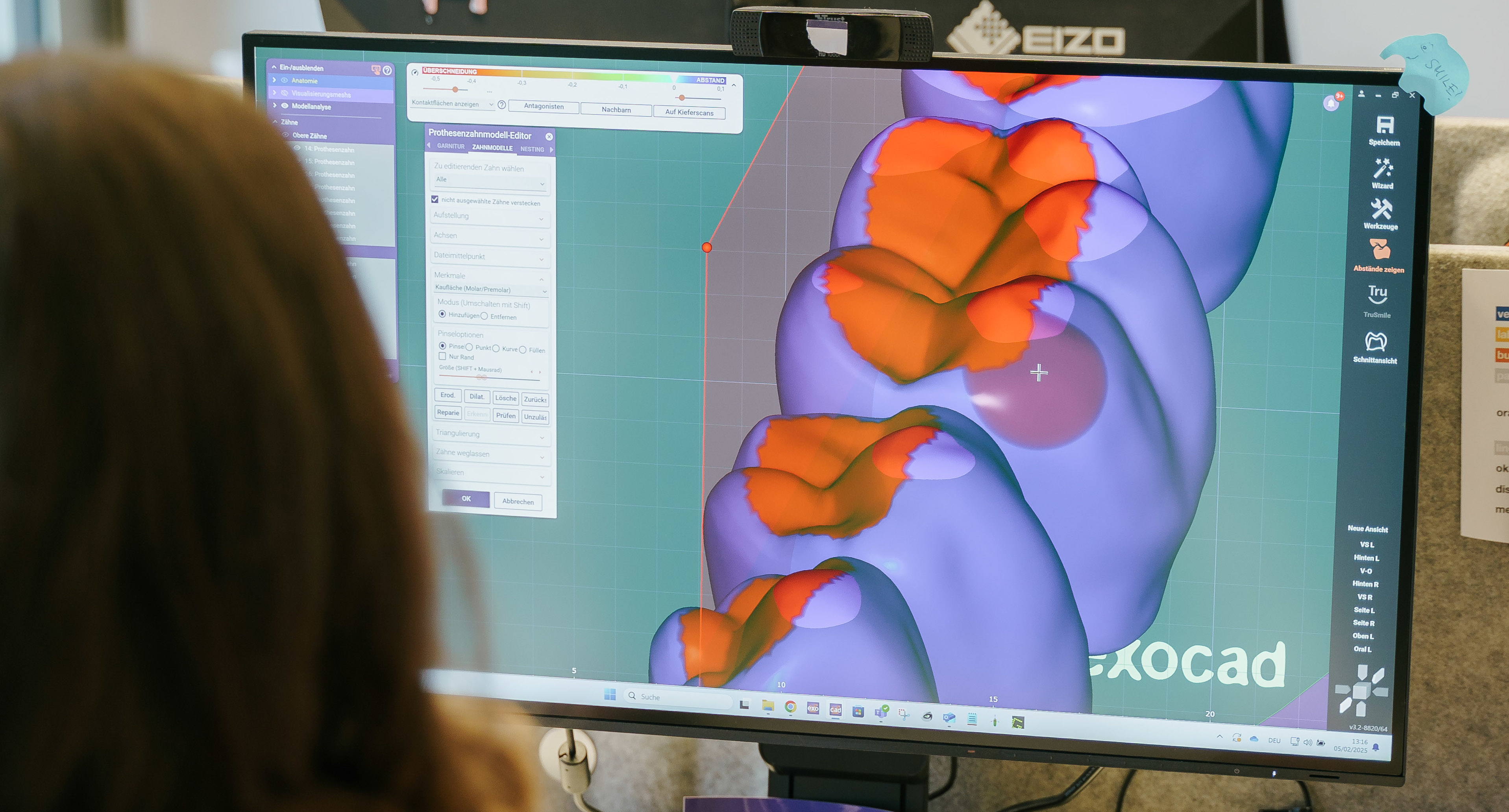

The most efficient and straightforward way to integrate your teeth is by utilizing one of our specialized services. Our team of experts is dedicated to ensuring a seamless integration process tailored to your specific needs. Upon receiving your request and the necessary data, we will carefully assess your requirements and provide a customized offer. This will guide you step-by-step to successfully integrate your teeth into our software suite.

Click here to get more information about the Technology Integration Services.

To integrate your teeth we need:

Your acrylic teeth must have similar measurements as the STL data, so that the tooth pockets that we digitally cut out of the denture base fit to the acrylic teeth. For this reason, it is required that you are using CAD/CAM systems (CNC-milling of tooth moulds) for your acrylic tooth production process. This determines the measurement accuracy of the tooth shapes. The quality of scanned teeth is not sufficient.

If you have recommended tooth setups as digital scans, we can use them to create tooth setups and/or presets (full denture) if you have multiple setups for the same teeth. Otherwise, we will create a compelling tooth setup in full occlusion and create the necessary denture tooth library set for you. The posterior teeth will be fixed in their setup and will be loaded into our software in perfect occlusion The anterior teeth will be loaded into the software in their "perfect setup" but can be repositioned by the customer.

If you have multiple setups for one tooth combination we can integrate predefined tooth setups in preset files. Presets enable quick and easy tooth setups in the software. For this we simply need the scans of all your setups.

We will create a compelling tooth setup in full occlusion and create the necessary denture tooth library set for you.

The posterior teeth will be fixed in their setup and will be loaded into our software in perfect occlusion. The anterior teeth will be loaded into the software in their "perfect setup" but can be repositioned by the customer.

If if there are multiple setups for one tooth combination we can integrate predefined tooth setups in preset files.

Presets enable quick and easy tooth setups in the software. For this we simply need the scans of all your setups as STL files.

There are several design and production methods for digital dentures, as you can see in the overview of our currently integrated tooth shapes.

We recommend enabling support for 3D-printing of tooth shapes with tooth material and milling teeth in (original) tooth material discs.The tooth shapes will then be integrated as open files so that printing/milling software can read the data for production. This decision determines our integration workflow and priorization of each integration project. With open files the user has the full flexibility in production options. The support of tooth shape scaling enables the user to optionally scale the teeth to fit the situation of the individual patient.

If you do not want to enable open files, only pre-manufactured acrylic teeth can be used. In this case there is also the possibility to only allow an export of a monoblock for try-in export that exports a merged open STL file of the tooth shapes and denture base fused together. The users can e.g. 3D-print the monoblock and use it as a try-in for the final denture that will get created afterwards (with the acrylic teeth).

We provide a variety of crown and bridges libraries for partial restorative treatments within our software solution.

Your teeth lineup shall be available for partial restorative treatments? Please contact exocad Technology Integration for further information.

Our experts will discuss potential integration solutions.contact us for further information. Our experts will discuss potential integration solutions.

The Technology Integration team is committed to providing top-notch services and fostering strong partnerships. We're here to support you every step of the way!